Paper on ACC design presented by University of Seville at the 5th European Conference on Supercritical Carbon Dioxide Energy Systems, Prague (Czech Republic)

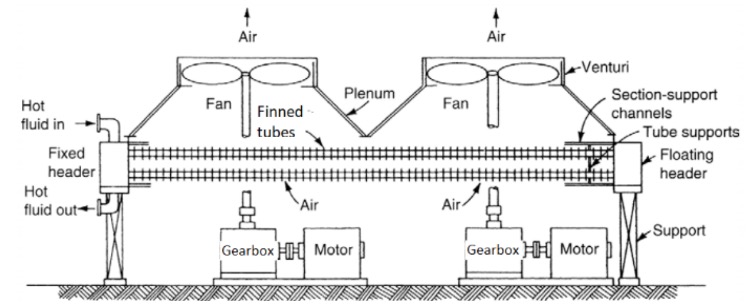

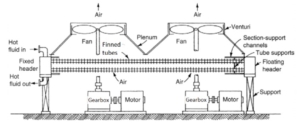

Schematic of ACC used as reference for SCARABEUS

The researchers at University of Seville have presented their work on the design and operation of air-cooled condensers for integration into Concentrated Solar Power plants using the SCARABEUS technology. This work has been carried out in the context of Work Package 5 (Techno-economic, Social and Environmental Assessments) but also in close collaboration with Work Package 4 (Air Cooled Condenser and Heat Exchanger Development).

Condensation of the working fluid at high ambient temperature is a differential feature of the SCARABEUS CONCEPT, setting it apart from standard supercritical Carbon Dioxide cycles where the working fluid cannot be condensed due to the unfeasibility of cooling CO2 down below the critical temperature. The design of condensers for operation at high pressure (~80 bar) and low temperature is therefore a innovation of the project. Also, the definition of operating strategies in order to reduce the negative impact of auxiliary (fan) power consumption on net cycle efficiency is critical in order to effectively attain the thermodynamic superiority of the SCARABEUS concept.

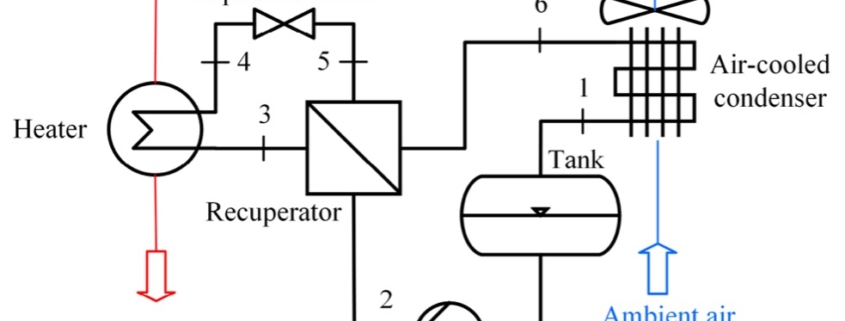

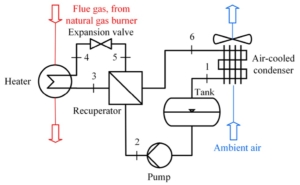

Flow chart of the Air Cooled Condenser design code

The paper can be downloaded free of charge from the conference website (link). Check the abstract below:

The SCARABEUS project investigates the use of CO2–based mixtures as working fluid in power cycles for nextgeneration Concentrated Solar Power plants. These fluids exhibit a critical temperature higher than pure CO2, enabling dry condensation of the working fluid even at the high ambient temperatures typical of sites with a high solar radiation. As a consequence, the SCARABEUS power cycle achieves higher thermal efficiency than standard sCO2 cycles, whose performance deteriorates significantly with ambient temperature. In any case, the actual feasibility of this concept is still to be confirmed by a complete techno-economic assessment. To that purpose, it is critical to accurately estimate the power consumption of the Heat Rejection Unit (HRU), which is one of the most important parasitic loads of the system.

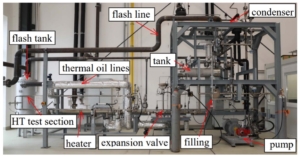

Bearing all this in mind, this manuscript presents the design of a horizontal, direct air-cooled condenser (ACC). The bundle geometry proposed is comprised of seven tubes in three passes, with a staggered arrangement. The complete thermal model, developed in MatLab, has been already disclosed by the SCARABEUS consortium in a previous paper, and validated both experimentally in a dedicated test rig and against results obtained by the commercial software Xace®. The novelty in the present manuscript lies in the integration of this thermal model of the tubes with a complete design and integration tool of the whole heat rejection sub-system, including the design of a rotoronly axial fan and supporting frame. The impact of several design parameters (i.e., air temperature rise, acceptable hot pressure drops, tube length) is studied, taking into account auxiliary power consumption, footprint and cycle efficiency as main figures of merit. Two candidate mixtures are taken into account, identified in previous works by the same authors (85%CO2-15%C6F6 and 80%CO2-20%SO2), and a pure sCO2 case is also considered for the sake of comparison. The results show that, for a given gross cycle output, using pure sCO2 yields the smallest ACC with the lowest fan power consumption. Moreover, tube length and air face velocity are found to be the key-parameters driving the design process of an ACC, for which increasing tube length is always beneficial as far as the ACC design is concerned. Finally, various considerations regarding the role played by the optimum design of the ACC within the global optimisation of the power plant are made. It is found that the rationale employed for the design of the ACC may be in conflict with that used from an overall plant optimisation standpoint. It is hence concluded that the definition of the optimal design space of an Air-cooled Heat Exchanger (ACHE) must be included in the global optimisation of the power plant.