The SCARABEUS teams at City, University of London, University of Seville and Baker Hughes have recently published a paper authored jointly by the three institutions. This scientific publication is the result from the collaboration between Work Package 3 – Turbomachinery Design and Work Package 5 – Techno-economic, Social and Environmental Assessments. In particular, the team at University of Seville has provided the boundary conditions for the design of the turbines, which has been carried out by City, University of London and Baker Hughes jointly. Then, the impact of the resulting turbomachinery efficiency on cycle performance has been assessed in WP5.

The paper has been published in volume 230 of Applied Thermal Engineering (Elsevier) and it is available in Open Access on the publisher’s website (link). Check the abstract below:

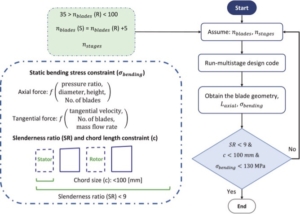

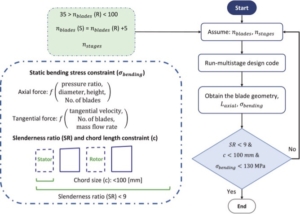

The utilisation of certain blends based on supercritical CO2 (sCO2), namely CO2/TiCl4, CO2/C6H2 and CO2/SO2, have been found to be promising for enhancing the performance of power cycles for Concentrated Solar Power (CSP) applications; allowing for up to a 6% enhancement in cycle efficiency with respect to a simple recuperated CO2 cycle, depending upon the nature of the used blend and the cycle configuration of choice. This paper presents an investigation of the impact of adopting these sCO2-based blends on the flow path design for a multi-stage axial turbine whilst accounting for aerodynamic, mechanical and rotordynamic considerations. This includes assessing the sensitivity of the turbine design to selected working fluid and imposed optimal cycle conditions. Ultimately, this study aims to provide the first indication that a high-efficiency turbine can be achieved for a large-scale axial turbine operating with these non-conventional working fluids and producing power in excess of 120 MW. To achieve this aim, mean-line aerodynamic design is integrated with mechanical and rotordynamic constraints, specified based on industrial experience, to ensure technically feasible solutions with maximum aerodynamic efficiency. Different turbine flow path designs have been produced for three sCO2 blends under different cycle boundary conditions. Specifically, flow paths have been obtained for optimal cycle configurations at five different molar fractions and two different turbine inlet pressure and temperature levels of 250 & 350 bar and 550 & 700 °C respectively. A total-to-total turbine efficiency in excess of 92% was achieved, which is considered promising for the future of CO2 plants. The highest efficiencies are achieved for designs with a large number of stages, corresponding to reduced hub diameters due to the need for a fixed synchronous rotational speed. The large number of stages is contrary to existing sCO2 turbine designs, but it is found that an increase from 4 to 14 stages can increase the efficiency by around 5%. Ultimately, based on the preliminary cost analysis results, the designs with a large number of stages were found to be financially feasible compared to the designs with a small number of stages.

Flowpath optimisation methodology used in the paper