City, University of London and Baker Hughes have been working on the turbomachinery design for the SCARABEUS project. A 130 MW axial turbine is designed to produce a net power output from the cycle of ~100 MWe. The design process starts by identifying the aerodynamic and mechanical design constraints based on industrial and academic experience, while these constraints are applied to produce the preliminary design using the available loss correlations. A further design assessment is conducted using numerical CFD/FEA simulations to optimise the turbine blades for performance maximisation and to ensure a safe and reliable operation.

This work was presented at the ASME conference held in Rotterdam (The Netherlands), June 13-17, by Abdelrahman Abdeldayem, from City, University of London on behalf of the team.

The paper is available in Open Access on the publisher’s website: https://doi.org/10.1115/1.4055232

Abstract

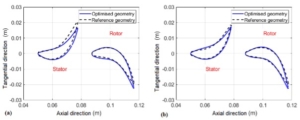

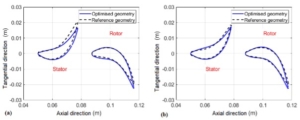

Within this study, the blade shape of a large-scale axial turbine operating with sCO2 blended with dopants is optimized using an integrated aerodynamic-structural three-dimensional (3D) numerical model, whereby the optimization aims at maximizing the aerodynamic efficiency whilst meeting a set of stress constraints to ensure safe operation. Specifically, three candidate mixtures are considered, namely, CO2 blended with titanium tetrachloride (TiCl4), hexafluorobenzene (C6F6), or sulfur dioxide (SO2), where the selected blends and boundary conditions are defined by the EU project, SCARABEUS. A single passage axial turbine numerical model is setup and applied to the first stage of a large-scale multistage axial turbine design. The aerodynamic performance is simulated using a 3D steady-state viscous computational fluid dynamic (CFD) model while the blade stress distribution is obtained from a static structural finite element analysis simulation (FEA). A genetic algorithm is used to optimize parameters defining the blade angle and thickness distributions along the chord line while a surrogate model is used to provide fast and reliable model predictions during optimization using a genetic aggregation response surface. The uncertainty of the surrogate model, represented by the difference between the surrogate model results and the CFD/FEA model results, is evaluated using a set of verification points and is found to be less than 0.3% for aerodynamic efficiency and 1% for both the mass-flow rate and the maximum equivalent stresses. The comparison between the final optimized blade cross section has shown some common trends in optimizing the blade design by decreasing the stator and rotor trailing edge thickness, increasing the stator thickness near the trailing edge, and decreasing the rotor thickness near the trailing edge and decreasing the rotor outlet angle. Further investigations of the loss breakdown of the optimized and reference blade designs are presented to highlight the role of the optimization process in reducing aerodynamic losses. It has been noted that the performance improvement achieved through shape optimization is mainly due to decreasing the endwall losses with both the stator and rotor passages.