New SCARABEUS paper discusses the benefits brought about by the utilization of Carbon Dioxide mixtures in supercritical power cycles applied to Concentrated Solar Power plants

The SCARABEUS consortium (University of Seville, University of Brescia, Politecnico di Milano and LEAP) has just published in Energy journal their recent research in the area of cycle performance. This research paper provides a through analysis of the underpinning reasons why the utilization of mixtures enables higher maximum (thermal) efficiency and it also reveals the best combinations of cycle layout and working fluid composition.

The paper, whose abstract is pasted below, is now available in Open Access on the publisher’s website (link). Check it out now!

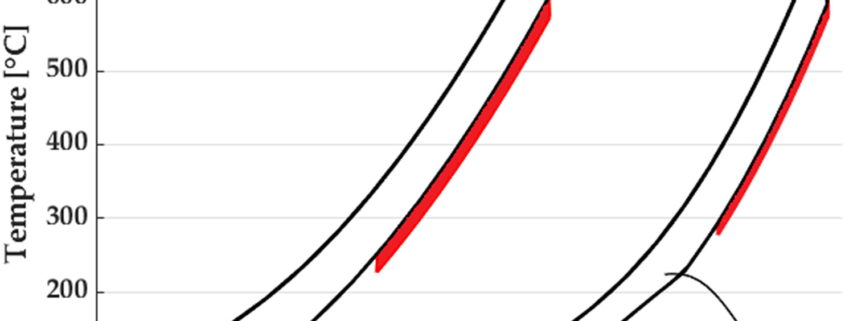

The present paper explores the utilisation of dopants to increase the critical temperature of Carbon Dioxide (sCO2) as a solution towards maintaining the high thermal efficiencies of sCO2 cycles even when ambient temperatures compromise their feasibility. To this end, the impact of adopting CO2-based mixtures on the performance of power blocks representative of Concentrated Solar Power plants is explored, considering two possible dopants: hexafluorobenzene (C6F6) and titanium tetrachloride (TiCl4). The analysis is applied to a well-known cycle -Recuperated Rankine- and a less common layout -Precompression-. The latter is found capable of fully exploiting the interesting features of these non-conventional working fluids, enabling thermal efficiencies up to 2.3% higher than the simple recuperative configuration. Different scenarios for maximum cycle pressure (250–300 bar), turbine inlet temperature (550–700ºC) and working fluid composition (10–25% molar fraction of dopant) are considered. The results in this work show that CO2-blends with 15–25%(v) of the cited dopants enable efficiencies well in excess of 50% for minimum cycle temperatures as high as 50ºC. To verify this potential gain, the most representative pure sCO2 cycles have been optimised at two minimum cycle temperatures (32ºC and 50ºC), proving the superiority of the proposed blended technology in high ambient temperature applications.