The Institute for Energy Systems and Thermodynamics at TU Wien getting ready for the testing campaign

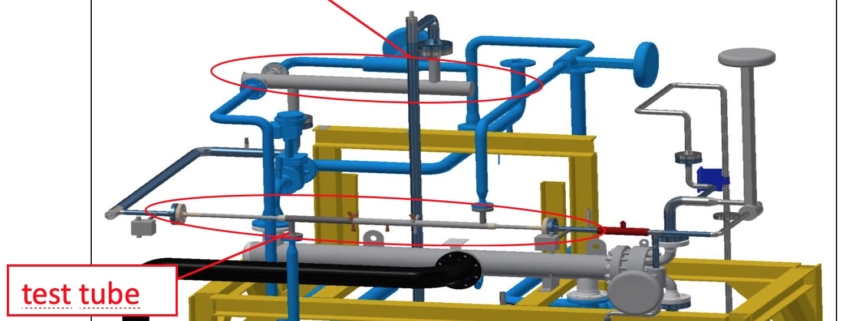

During the last months, IET concentrated on design tasks according to work package 4, where pre-tests for the design of the air-cooled condenser (ACC) and the recuperator (printed circuit heat exchanger) are planned. Therefor several modifications of the test rig are necessary, see Figure 1:

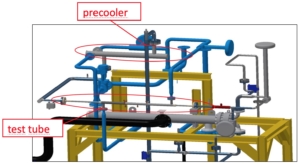

Figure 1: Modifications of test rig at IET. Grey: additional heat exchangers (precooler and test tube). Blue: cooling water lines.

With the combination precooler and test-test-tubes, desuperheating and condensation experiments at a pressure level of p = 66 bar are planned. For pure CO2 the corresponding condensation temperature is 26,11 °C. Maximum CO2-temperature will be 180 °C, so different desuperheating / condensation tests are possible depending on entrance temperature of CO2 and cooling load of the precooler. In the first step, experiments with pure CO2 will be done, then testing with blended CO2 by adding a refrigerant (R1234ze) will follow. Adding a blend will give a first impression of about the behaviour of a mixture instead of pure CO2 and will help to train the handling of harmless mixtures on the rig, in the perspective of the future planned tests with other blends being developed and tested at UBS and POLIMI.

Figure 2: Left: Precooler delivered from KELVION. Right: test rig under modification.